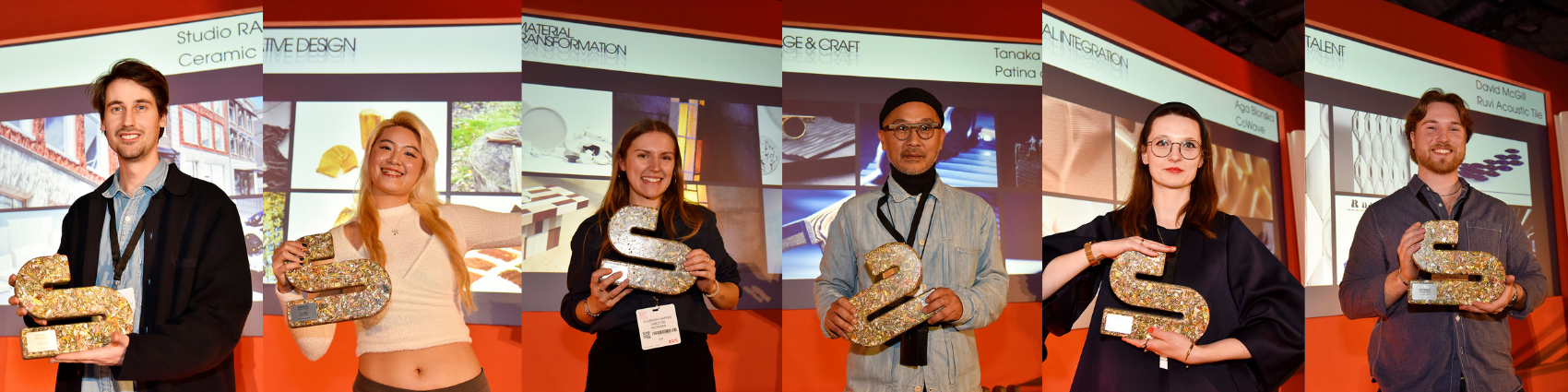

After a very successful Awards evening on Wednesday 4 February 2026 at Surface Design Show we are delighted to showcase this years winners! Judged by an esteemed panel of design and architectural professionals, the Surface Design Awards have been designed to encourage both small and large practises or projects to gain recognition from their peers.

Thank you to Revive Innovations for creating our amazing trophies made of 70 recycled CD's in line with this years theme: Material Evolution.

The Awards took place in the Auditorium of the Business Design Centre, hosted by Hamish Kilburn.

Find out more about our winners below:

)

)

)